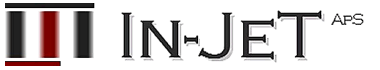

COMPOSITION

Ecosystem for Collaborative Manufacturing Processes – Intra- and Interfactory Integration and Automations

The COMPOSITION project is a 36 month Research and Innovation Action (RIA) co-funded by the European Commission through the Horizon 2020 Framework Programme for Research and Innovation under the Factory of the Future objectives.

COMPOSITION will develop an integrated information management system (IIMS) which optimises the internal production processes by exploiting existing data, knowledge and tools to increase productivity and dynamically adapt to changing market requirements. The project will also develop an ecosystem to support the interchange of data and services between factories and their suppliers with the aim to invite new market actors into the supply chain.

The first specific goal is thus to integrate data along the value chain inside a factory into one integrated information management system (IIMS) combining physical world, simulation, planning and forecasting data to enhance re-configurability, scalability and optimisation of resources and processes inside the factory. The second goal is to create a (semi-)automatic ecosystem, which extends the local IIMS concept to a holistic and collaborative system incorporating and inter-linking both the Supply and the Value Chains.

As proof-of-concept, the COMPOSITION operating system will be implemented, demonstrated and validated in two multi-sided pilots that show the modularity, scalability and re-configurability of the platform across multiple application domains. The first pilot in the biomedical device domain focuses manufacturing processes within one company (Intra-factory). The second pilot is in the lift manufacturing domain and demonstrates integration within ecosystem of recycling companies (Inter-factory).

Rationale

Requirements of modern production processes stress the need of greater agility and flexibility leading to faster production cycles, increased productivity, less waste and more sustainable production. At the factory level, decisions need to be supported by detailed knowledge about the production process and its interplay with external entities. Unfortunately, historical and live data that generates this knowledge is becoming more and more distributed across both the Supply Chain and the Value Chain, and few if any solutions are available that can easily tackle the implied challenges.

Project data

The ability of automatizing, as much as possible, the preliminary coordination and negotiations activities involved in setting up supply chains for specific needs, in an open marketplace-like fashion, could greatly improve the ability of factories to quickly react to external challenges and driving forces.

Supply Chain

Sharing product and production data with other actors in the supply chain (sub-manufacturers, suppliers) seldom occurs and, when this happens, is generally on an ad-hoc basis. Where specific systems have been developed in actual factories, they are often bespoke, non-transparent, inflexible, and provide few if any client-side feedback.

Value Chain

Suitable tools to track production efficiency (scrap, re-work, available capacity, resources and energy consumption) are missing or lacking features in most enterprises. For SMEs the scenario is even worse as they seldom adopt such tools and mainly rely on personal abilities of involved employees. Even within multinational manufacturing facilities, the ability to accurately compare production indicators, e.g. Key Performance Indicators (KPIs), across value streams and across multiple sites is still quite uncommon.

Architecture

From a very high-level standpoint, the COMPOSITION ecosystem will both support existing partnerships, by dramatically improving data exchange and coordination in existing supply chains, and boost participation of new stakeholders to existing chains, either on a temporary basis or in longstanding relationships.

As can be noticed by looking at the integrated architecture depicted below, the COMPOSITION marketplace supports by design existing supply chains, enhancing their efficiency and autonomy (orange and yellow islands). However the COMPOSITION greatest contribution is on setting-up new market possibilities for newcomers, both in single supply islands (as for the company B) and in cross-island (or cross-community) interactions, thus empowering new, possibly highly impacting, business opportunities.

Technology

The COMPOSITION marketplace approach introduces collaborative models which include Forecasting, Design and Product Development, Manufacturing and Transportation/Distribution sub-models. Decision support tools will simulate and forecast virtual distributed manufacturing network performance and thereupon select virtual distributed manufacturing networks and process management strategies optimized for KPIs such as cost, energy, emission, other environmental footprint, to be ultimately implemented in and used for production. COMPOSITION will also employ an IoT-stemming approach based on wireless sensor-actuator networks for retrofitting existing plants, which must be installed to monitor and control factory processes in real time. The purpose of such a Cyber-Physical System (CPS) is to gather the data from the real world and to represent it in the virtual world managed by the IIMS. Different kinds of sensors will need to be integrated with existing information systems in the plant.

The COMPOSITION architecture proposes to adapt and deploy a blockchain implementation as the central component of its log-oriented architecture. The log-oriented architecture is adopted in order to support non-repudiation of data and decentralization of use in the COMPOSITION manufacturing and supply chains. In this context the blockchain will be used to provide an audit trail for manufacturing and supply chain data, enabling both product data traceability and secure access for stakeholders. The work will adapt a blockchain implementation considering architectural properties for transactions and event data, units of sharing, log update and distribution, client model and secure access and immutable storage, and back-bone replication principles.

Expected Project Outcomes

The collaborative manufacturing and logistics ecosystem proposed by COMPOSITION is expected to lead to strong productivity increase. Assuming that discrete manufacturing accounts for 2/3 of all manufacturing in Europe, the increase in the industry sector’s value added from the anticipated improvements from COMPOSITION is in the order of 730 billion euro corresponding to an increase in the overall industrial productivity of 19%-points.COMPOSITION tools and open platform create ecosystems for interoperability among the different levels of heterogeneous and complex interoperability of MES and CPS technologies and is especially attractive in relation to Europe’s innovative SMEs, who generally are more agile and receptive to change, and in greater need for dynamic and interoperable solutions. The new agent-based modelling and data acquisition tools with open standardised connectors and allows enterprises to instantiate virtual manufacturing processes and systems and link them into the semantically-enriched factory model and thus use legacy MES data as a source for a “Digital Twin” factory in a cloud environment.COMPOSITION will also result in an improved understanding of process parameters and profiles from continuous monitoring of operational or environmental variances.

In-JeT’s role in the project

In-JeT is the Innovation Manager of the COMPOSITION project. We are participating in the iterative requirement process and develop procedures for capturing Lessons Learned and perform requirements re-engineering, constantly keeping the project aligned with its objectives and vision. In-JeT’s role is also to perform the business modelling, where we, together with partners, develop concepts and methods for value models. Further, it is In-JeT’s role to develop and maintain the COMPOSITION website.

Partners

- Fraunhofer Institute for Applied Information Technology (Coordinator), Germany

- Boston Scientific Limited (Clonmel) (User partner), Ireland

- KLEEMANN Hellas SA (User partner), Greece

- Atlantis Engineering SA, Greece

- Nextworks, Italy

- ELDIA SA (User partner), Greece

- Tyndall National Institute – University College Cork, Ireland

- In-JeT ApS, Denmark

- Centre for Research and Technology Hellas, Greece

- CNet Svenska AB, Sweden

- Istituto Superiore Mario Boella, Italy

- Atos Spain SA, Spain

Funding

Co-funded by the European Commission Horizon 2020 Research and Innovation Programme.